Are you considering entering the world of meat processing? You’re not alone! The meat processing industry is booming, with a growing demand for quality meat products. In fact, studies show that consumer preferences are shifting towards locally sourced and sustainably produced meats. This makes it an opportune time to explore how to start a meat processing plant. A meat processing plant is a facility where livestock is slaughtered and processed into various meat products for distribution and sale. In this guide, we’ll cover everything you need to know to get your meat processing venture off the ground.

- Discover the essential steps for starting your meat processing plant.

- Learn about market research and understanding your competitors.

- Understand the legal requirements and necessary permits.

- Explore funding options and financial planning.

- Find out how to create a robust business plan.

- Get tips on marketing and branding your meat processing business.

1. What is a Meat Processing Plant?

A meat processing plant is a facility designed to handle the slaughtering and processing of animals for meat. This includes various activities such as cutting, packaging, and distributing meat products. It’s essential to grasp the full scope of operations in such a facility, which typically involves:

- Slaughtering: The humane killing of livestock.

- Processing: Cutting and preparing meat for sale.

- Packaging: Ensuring products are safely packaged for distribution.

- Quality Control: Maintaining high standards of hygiene and safety.

Understanding these processes is vital as they directly impact the quality of the products you will offer. If you’re passionate about meat quality and safety, starting a meat processing plant might just be the right venture for you!

2. Why Start a Meat Processing Plant?

Before jumping into the logistics, let’s discuss why you might want to start a meat processing plant. Here are some compelling reasons:

| Reason | Description |

|---|---|

| Growing Market Demand | Consumers are increasingly seeking fresh and locally sourced meats, presenting a lucrative opportunity. |

| Profitability | The meat industry is known for its high-profit margins, especially for quality products. |

| Community Impact | Supporting local farmers and providing jobs can strengthen your community and enhance your business’s reputation. |

Starting a meat processing plant not only fulfills a market need but also allows you to make a positive impact. As consumer preferences shift, positioning your business to meet these demands can lead to long-term success. Plus, there’s something incredibly rewarding about producing quality meat products that people enjoy. So, if you’re ready to embark on this journey, let’s dive deeper into the steps required to establish your own meat processing plant!

3. Conduct Market Research for Your Meat Processing Plant

Market research is a crucial step when learning how to start a meat processing plant. It involves gathering information about your target market, understanding consumer preferences, and analyzing your competition. Here’s how to effectively conduct market research:

- Identify Your Target Audience: Who are your potential customers? Are you targeting local restaurants, grocery stores, or direct consumers?

- Analyze Competitors: Look at existing meat processing plants in your area. What products do they offer? What are their strengths and weaknesses?

- Gather Industry Data: Use reports and studies to understand current trends in the meat processing industry. What products are gaining popularity?

By conducting thorough market research, you can pinpoint opportunities for differentiation and ensure that your business model aligns with market demands. Additionally, consider creating surveys or focus groups to gather direct feedback from potential customers.

4. Develop a Comprehensive Business Plan for Your Meat Processing Plant

Creating a solid business plan is essential for your success. It serves as a roadmap for your operations and helps you secure funding. A well-crafted business plan for a meat processing plant should include the following components:

| Section | Description |

|---|---|

| Executive Summary | A brief overview of your business and its objectives. |

| Market Analysis | Insights from your market research, including target market and competition. |

| Marketing Strategy | How you plan to promote your products and reach customers. |

| Operations Plan | Details on the production process, equipment needed, and workforce requirements. |

| Financial Projections | Projected income, expenses, and profitability over the next few years. |

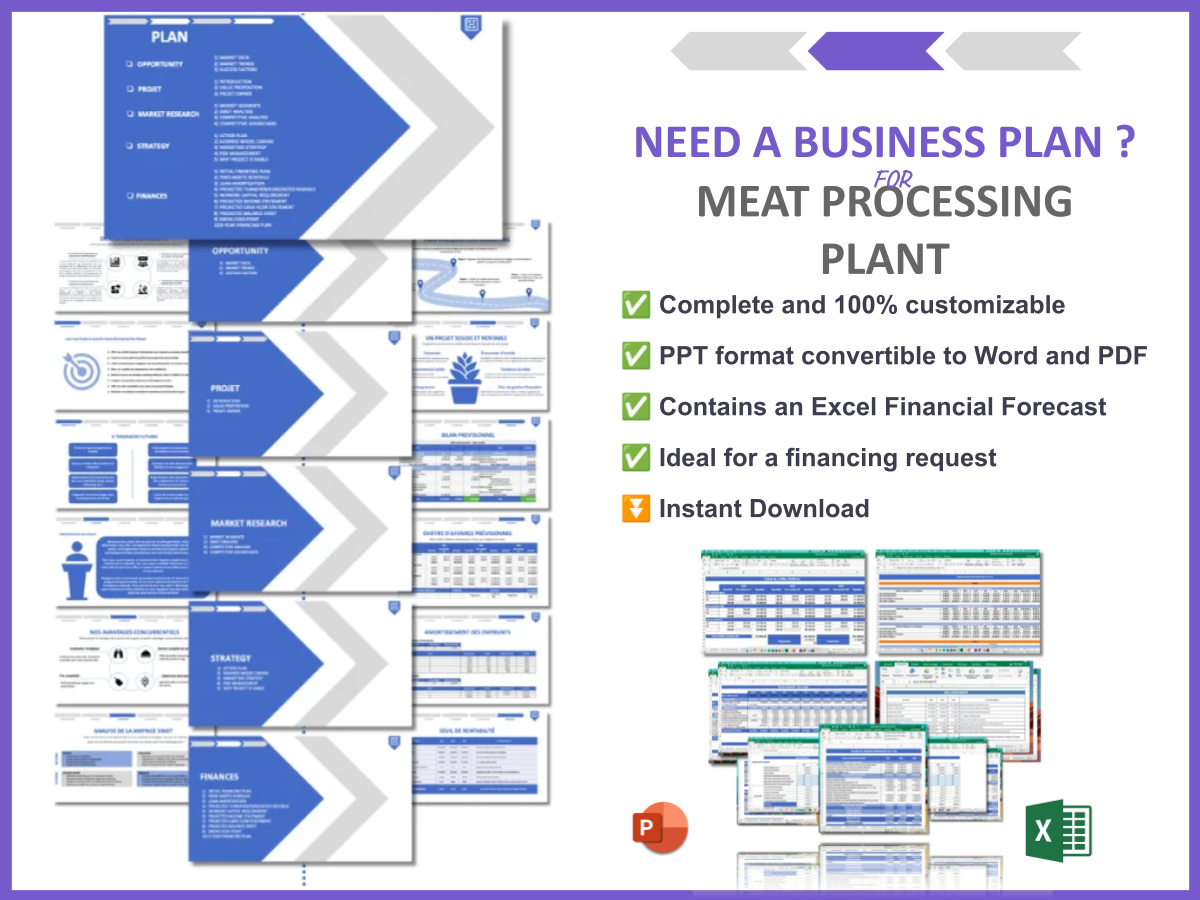

I recommend checking out this business plan template for Meat Processing Plant. It’s super detailed and can save you a ton of time! Having a clear business plan not only helps you stay organized but also demonstrates to potential investors that you are serious about your venture.

In summary, a comprehensive business plan is a vital tool for any entrepreneur looking to start a meat processing plant. It lays the groundwork for your business and guides your decision-making as you move forward. So, take the time to develop a plan that reflects your vision and goals!

5. Choose a Suitable Location for Your Meat Processing Plant

Selecting the right location for your meat processing plant is crucial for your business’s success. The location impacts logistics, operational efficiency, and accessibility to your target market. Here are key factors to consider:

- Proximity to Suppliers: Being close to livestock suppliers and feed can reduce transportation costs and improve freshness.

- Transportation Access: Ensure that your location has good access to major roads and transport hubs for efficient distribution of your products.

- Zoning Regulations: Check local zoning laws to ensure that your chosen location is permitted for industrial use, particularly for food processing.

- Market Access: Consider how close you are to your target customers, whether they are local grocery stores, restaurants, or direct consumers.

Once you have narrowed down potential locations, it’s wise to conduct a SWOT analysis (Strengths, Weaknesses, Opportunities, Threats) to evaluate each option’s viability. This will help you make an informed decision that aligns with your business goals.

6. Understand Legal Requirements for Starting a Meat Processing Plant

Starting a meat processing plant comes with a host of legal requirements that you must navigate carefully. Compliance with federal, state, and local regulations is essential for operating legally and safely. Here’s what you need to consider:

| Legal Requirement | Description |

|---|---|

| Licenses and Permits | Obtain the necessary licenses to operate a meat processing facility, which may vary by state. |

| Health and Safety Regulations | Comply with food safety standards set by organizations like the USDA and FDA. |

| Environmental Regulations | Ensure that your operations comply with environmental laws regarding waste disposal and emissions. |

It’s highly recommended to consult with a legal expert who specializes in food processing to help you navigate these regulations. They can provide guidance on how to comply with all necessary laws and avoid potential fines or shutdowns.

Understanding the legal landscape is critical as it not only protects your business but also builds trust with your customers, ensuring that they receive safe and high-quality meat products. Take the time to educate yourself about these requirements to set a strong foundation for your meat processing plant.

7. What Equipment Do You Need for Your Meat Processing Plant?

Equipping your meat processing plant with the right tools and machinery is essential for efficient operations. The equipment you choose will impact the quality of your products and the overall productivity of your facility. Here’s a list of essential equipment needed for a successful meat processing plant:

- Slaughtering Equipment: Includes stunning devices, knives, and tables designed for humane processing.

- Processing Equipment: This includes meat saws, grinders, and mixers for preparing various meat products.

- Packaging Machines: Automated or semi-automated machines that seal meat products for distribution.

- Refrigeration Units: Essential for maintaining the freshness and safety of meat products during processing and storage.

- Cleaning Equipment: Pressure washers and sanitizing systems to ensure hygiene standards are met.

Investing in quality equipment can significantly enhance your operational efficiency and product quality. It’s also important to consider the layout of your meat processing plant to ensure that equipment is arranged for optimal workflow. For example, the slaughtering area should be separate from the processing and packaging areas to maintain hygiene.

8. Secure Funding for Your Meat Processing Plant

Starting a meat processing plant requires a significant financial investment. Securing the necessary funding is crucial to cover costs such as equipment, facility setup, and initial operating expenses. Here are some potential funding options:

| Funding Source | Description |

|---|---|

| Bank Loans | Traditional financing option where you apply for a loan based on your business plan and financial projections. |

| Grants | Look for government or private grants aimed at supporting agricultural and food processing ventures. |

| Investors | Seek out investors who are interested in funding food industry startups. Be prepared to pitch your business plan! |

When seeking funding, having a well-prepared business plan can make a significant difference. It showcases your understanding of the meat processing industry and your strategy for success. Additionally, consider networking with local agricultural organizations or attending industry events to meet potential investors.

Securing the right funding will provide you with the financial stability needed to launch and grow your meat processing plant. With the right resources in place, you can focus on producing high-quality meat products that meet consumer demands.

9. Set Up Quality Control and Safety Procedures

Ensuring high standards of quality and safety is paramount in a meat processing plant. Implementing effective quality control measures will not only protect your customers but also enhance your business’s reputation. Here are key components to consider:

- Hygiene Practices: Establish strict hygiene protocols for all staff, including handwashing stations and sanitation procedures.

- Regular Inspections: Conduct routine inspections of equipment and facilities to ensure compliance with safety standards.

- Quality Assurance Testing: Implement testing procedures for meat products to ensure they meet quality and safety standards before distribution.

It’s also important to stay updated on regulations from organizations like the USDA and FDA regarding food safety. Here’s a brief overview of common safety regulations:

| Regulation | Description |

|---|---|

| HACCP (Hazard Analysis Critical Control Point) | A systematic approach to food safety that identifies and controls potential hazards. |

| Sanitation Standard Operating Procedures (SSOPs) | Guidelines for maintaining cleanliness and hygiene throughout the processing facility. |

| Labeling Requirements | Ensure all meat products are accurately labeled with ingredients, handling instructions, and expiration dates. |

By prioritizing quality control and safety procedures, you can build trust with your customers and ensure that your meat processing plant complies with all necessary regulations. This commitment to quality can set you apart in a competitive market.

10. Develop Your Brand Identity

Your brand identity is crucial for standing out in the competitive meat processing industry. A strong brand can help you connect with customers and establish a loyal customer base. Here’s how to create an impactful brand identity:

- Define Your Brand Values: What principles guide your business? Focus on aspects like sustainability, quality, and community support.

- Create a Memorable Logo: A professional logo can help customers instantly recognize your brand. Consider hiring a designer to create a unique logo that reflects your values.

- Develop a Brand Voice: Decide on the tone of your communication, whether it’s friendly, professional, or informative. Consistency is key!

Once you have established your brand identity, ensure it is consistently reflected across all platforms, including packaging, marketing materials, and your website. A cohesive brand presence will enhance your credibility and attract more customers to your meat processing plant.

In a world where consumers are increasingly conscious of where their food comes from, a strong brand identity can resonate with their values and preferences. By prioritizing your brand, you set the stage for long-term success in the meat processing market.

11. Create a Marketing Strategy for Your Meat Processing Plant

Once your meat processing plant is up and running, you need to attract customers. Developing a solid marketing strategy is essential for reaching your target audience and promoting your products. Here are some effective marketing tactics to consider:

- Social Media Marketing: Utilize platforms like Instagram and Facebook to showcase your products, share recipes, and engage with customers.

- Local Partnerships: Collaborate with local restaurants and grocery stores to feature your meat products. This can help you gain visibility and credibility.

- Content Marketing: Start a blog on your website that shares insights about meat processing, recipes, and sustainability. This can establish your brand as an authority in the industry.

It’s also crucial to track the effectiveness of your marketing efforts. Consider using tools like Google Analytics to measure website traffic and engagement, allowing you to adjust your strategy accordingly. Here’s a brief overview of key performance indicators (KPIs) to monitor:

| KPI | Description |

|---|---|

| Website Traffic | The number of visitors to your site, indicating the effectiveness of your online presence. |

| Social Media Engagement | Likes, shares, and comments on your posts, reflecting audience interest and interaction. |

| Sales Growth | Monitoring changes in sales over time to assess the impact of your marketing strategies. |

By implementing a comprehensive marketing strategy, you can effectively promote your meat processing plant and attract a loyal customer base.

12. Hire and Train Your Team

Your team is the backbone of your meat processing plant. Hiring the right people and providing adequate training are crucial for maintaining high-quality standards and operational efficiency. Here’s how to build a strong team:

- Identify Key Roles: Determine the essential positions needed for your operations, such as production workers, quality control inspectors, and administrative staff.

- Recruitment: Use job boards, social media, and local networks to find qualified candidates. Look for individuals with experience in food processing or a passion for the meat industry.

- Training Programs: Develop comprehensive training programs that cover safety protocols, quality control measures, and operational procedures. Regular training updates are vital to keep your team informed about industry standards.

By investing in your team, you create a motivated workforce that is committed to producing high-quality meat products. A well-trained team can also help ensure compliance with safety regulations, further enhancing your business’s reputation.

13. Launch Your Meat Processing Plant

After all the planning and preparation, it’s time to launch your meat processing plant! This is an exciting phase where you put your hard work into action. Here’s a checklist to guide you through the launch process:

- Finalize Operations: Ensure that all equipment is set up, and safety protocols are in place.

- Conduct a Soft Launch: Consider starting with a soft launch to test your processes and gather feedback before a grand opening.

- Promote Your Launch: Use social media, local press, and community events to announce your opening and attract customers.

- Monitor Performance: Keep an eye on operations, customer feedback, and sales to make adjustments as needed.

Launching your meat processing plant is just the beginning of your entrepreneurial journey. Stay adaptable and open to feedback, and continuously seek ways to improve your products and operations. With dedication and hard work, your meat processing venture can thrive in the competitive market.

Remember, the key to success in the meat processing industry lies in your commitment to quality, safety, and customer satisfaction. Good luck on your exciting new venture!

Conclusion

Starting a meat processing plant can be a rewarding venture that not only fulfills a market need but also allows you to make a positive impact on your community. By following the steps outlined in this guide, you’ll be well-prepared to navigate the complexities of the industry, from conducting market research to launching your facility.

As you embark on this exciting journey, remember to prioritize quality, safety, and customer satisfaction. Continuous improvement and adaptability will be your best allies in this competitive market. For further insights, I recommend checking out our articles on how to create a SWOT Analysis for Meat Processing Plant and how to plan a Meat Processing Plant Marketing Strategy. These resources will provide you with additional tools and strategies to enhance your business success.

FAQ

- What are the initial costs of starting a meat processing plant?

The initial costs can vary significantly depending on the scale of operations, equipment needed, and facility setup. Generally, you should budget for equipment, licenses, permits, and facility costs, which can range from tens of thousands to several hundred thousand dollars. - What licenses and permits do I need for a meat processing plant?

You’ll need various licenses and permits, including federal and state meat processing licenses, health department permits, and possibly environmental permits depending on your location. It’s essential to check local regulations for specific requirements. - How can I ensure food safety in my meat processing plant?

Implementing a Hazard Analysis Critical Control Point (HACCP) plan is crucial for food safety. Regular training for staff on hygiene practices and routine inspections of equipment will also help maintain high safety standards. - What type of meat products can I process?

You can process a variety of meats, including beef, pork, chicken, and lamb. Your product offerings can include fresh cuts, sausages, and value-added products like marinated or pre-cooked meats. - How do I find suppliers for my meat processing plant?

Establish relationships with local farmers, ranchers, and wholesalers. Attending agricultural fairs and industry events can also help you connect with potential suppliers in the meat processing industry. - What marketing strategies work best for a meat processing plant?

Utilizing social media, forming local partnerships, and engaging in community events can effectively promote your business. Additionally, creating a blog or website to share recipes and industry insights can attract customers. - How can I ensure quality control in my meat processing?

Establish a quality control program that includes regular product testing, staff training, and strict adherence to hygiene protocols. Monitoring the entire production process is key to maintaining quality. - What are the common challenges in starting a meat processing plant?

Challenges can include navigating regulatory requirements, managing operational costs, and building a customer base. Proper planning and market research can help mitigate these challenges. - How can I finance my meat processing plant?

Options for financing include bank loans, grants, and seeking investors. A well-prepared business plan can significantly improve your chances of securing funding. - What are the latest trends in the meat processing industry?

Current trends include a growing demand for organic and sustainably sourced meats, as well as increased consumer interest in transparency regarding meat origins and processing methods.